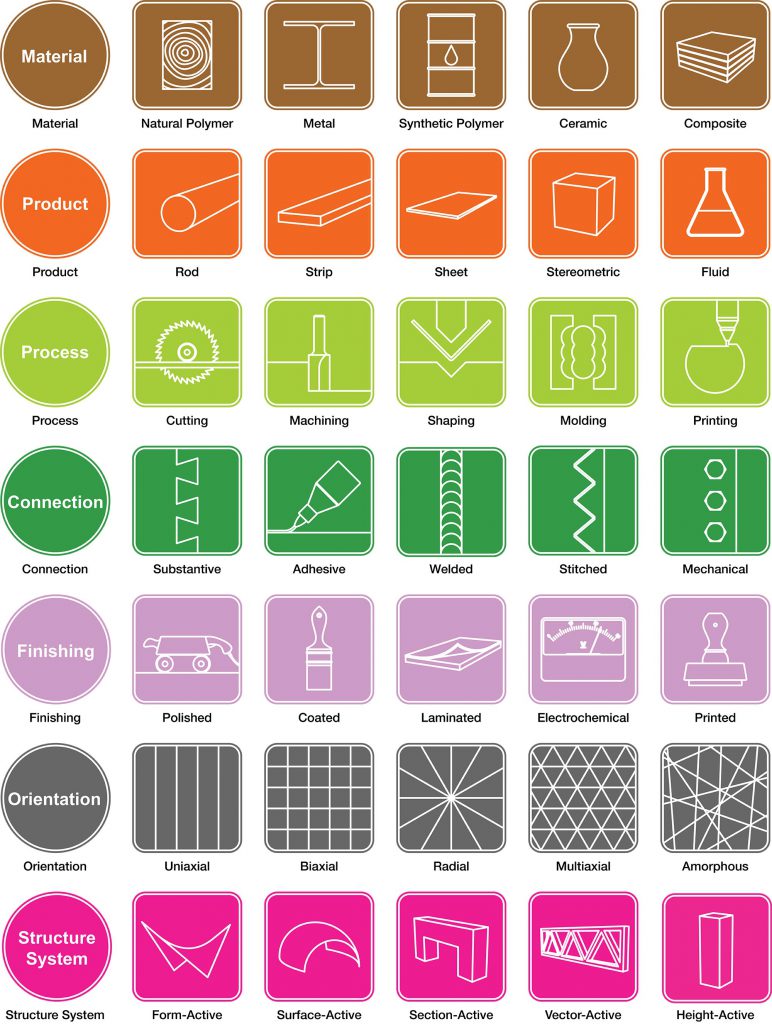

In the image above

In literature, there still are discussions about material differentiation. Often the discussion argues new materials that don’t fit well in former models. Most literature agrees on the distinction of material families in three groups being: Metals and Alloys, Ceramics and Glasses, Polymers and Elastomers (Martin, 1996). In some cases, the fourth group represents Composite Materials. Others argue that because of the exceptional qualities of Carbon, this material should be a group in itself (Bucquoye, 2002).

In this frame taxonomy, user-friendliness and materials used in artistic design are favored over a watertight theoretical theory. Because of a rich use of resin-based structures, composites are used as an individual sub-type. Because of wood being of great importance in construction and architecture, a distinction is made between natural polymers and chemical polymers.

Natural Polymers: The sub-type of natural polymers consists of all polymers that don’t have a chemical origin. In most cases, the material doesn’t consist of any oil based elements. In some literature, these natural polymers are described as natural composites. Being based on a combination of fibers of cellulose and collagen and having an advantage on the combination of both should fit them in composites better than polymers (Martin, 2006). Without going into molecular detail, in arts education, this distinction is difficult to teach. In this case, wood should be discussed together with polyester composites and epoxy honeycomb construction. This is why all materials consisting of mostly natural polymers are combined in this group.

Examples: Hardwood (Ash, Aspen, Birch, Cherry, Elm, Hazel, Mahogany, Maple, Oak, Teak), Softwood (Cedar, Pine, Spruce), Paper (Offset, Flattened, Layered), Cardboard (Honeycomb, Corrugated, Pressed), Leather, Skin, and Bone

Metals: The sub-type of metals consists of all materials consisting of a metallic bonding of electrons. Both metals and alloys are represented in this group.

Examples: Base metals (Aluminum, Copper, Iron, Tin, Lead, Nickel, Titanium, Zinc), Noble metals (Silver, Gold, Platinum), Metals used in alloys (Chrome, Cobalt, Magnesium, Nickel), and Alloys (Bronze, Brass, Cast Iron, Steel)

Synthetic Polymers: The sub-type Synthetic Polymers consists of all oil-based materials. Both polymers and elastomers are included in this sub-type.

Examples: Thermosetting Polymers (Polyester, Bakelite, Melamine resin, Epoxy resin), Thermoplastic Polymers (EVA, PTFE, ETFE, PET, PVC, PP PE), and Elastomers (Neoprene, Silicone)

Ceramic Materials: The sub-type Ceramics consist of all materials that are no metal or polymer. The sub-type includes stone like products as well as glass.

Examples: Traditional Ceramics (Pottery, Terracotta, Stone, porcelain), Technical Ceramics, and Glass.

Composites: The sub-type Composites consists of matrix materials, within which the combination of material properties is superior to those of the individual components.

Examples: Resin Sandwiches, Carbon Sandwiches, and Reinforced Components.

The sub-types of Material Products consist of a combination of standards used in metal, wood and ceramic industries. Some distinctions seem unnecessary at first sight. For instance, a narrow plate can be a strip, and a narrow strip can be a rod. In application in design and geometry and communication in workshops and education, the distinction proved rather valuable.

Rod: A rod is a product of a long length with a width to height ratio of about 1 to 1. By using these materials in, for instance, weaving and wickerwork won’t harm the structure geometrically.

Strip: A strip is a product of a long length which is wider than its thickness. The resistance while bending the material is different in one direction to the other. Using these products in double curved geometry will affect the behavior of the strip along its line.

Plate: A plate is a thin product with a surface area that is no more than two to three times longer than its width.

Stereometric: A stereometric product has a thickness in x, y to the z-direction. The thickness of x to y to z is one to another no more than two to three times bigger.

Fluid: A fluid is a product in a liquid state.

The type of Material Processing consists of procedures that can be used to manipulate Material Products (Ashby et al., 2007; Kula, 2013).

Cutting: The sub-type Cutting consists of all procedures that deal with segmentation.

Examples: Procedures using material removal (saw, water-, sand-, and laser-cutting, burning) and Procedures without material removal (cutting, nibbling, and punching).

Machining: The sub-type Machining consists of all procedures that involve manipulation of solid materials.

Examples: Drilling, Milling, Material Turning, and Sanding.

Shaping: The sub-type Shaping consists of all procedures that relate to

Examples: Bending, Folding and Embossing

Molding: The sub-type Molding consists of all procedures that involve shaping liquid products. In the process, the products harden over time.

Examples: Casting, Forging, and Extrusion.

Printing: The sub-type Printing consists of all 3D printing procedures.

Examples: Printing Procedures: LOM-Laminating, and Fused Material Deposition.

The type Material Connection consists of procedures that involve the joining of materials. The description is chosen as a noun to communicate a part of a design instead of an action (Ashby et al., 2007).

Substantive: In Substantive connections, no additives are used. The connection is created by machining of the material or product to a large extent. Glue can be used to support the connection but has no crucial role in its structural integrity.

Examples: Dovetail-, Tenon-, and Tongue-Connection

Adhesives: In Adhesive Connections, adhesive play the most important role.

Examples: Glue, Tape, and Mortar.

Welding: The sub-type Welding involves all procedures that join products using heat. Both procedures that do use additives and don’t belong to this group.

Examples: Soldering, Arch-, MIG-, TIG-, Friction-, and Laser-welding.

Stitched: Stitched connections involve all joints created by a thread.

Examples: Straight, Zigzag, Running, and Back-stitch

Mechanical: The sub-type of fasteners involves all connections using mechanical devices.

Examples: Bolt, Nail, Screw, and Rivet

The type Material Finishing involves all procedures used for finalizing the surface of a product or object. This treatment can have ornamental value, protective value or a combination of both (Ashby et al., 2007; Kula, 2013).

Polishing: The sub-type Polishing contains all techniques used to smoothen a surface. All procedures contain continuous friction and material removal. Sometimes an additive is used to accelerate the process.

Examples: Sanding, Polishing, and Sand-blasting.

Coating: The sub-type Coating involves all wet surface treatment applied without electrical charge. Most coatings dry over time.

Examples: Paint, Varnish, Enamel, and Glaze.

Laminating: The sub-type Laminating involves all dry surface treatment. Most laminating procedures involve the use of adhesives to connect the laminate to its surface.

Examples: Wood Veneer, Plastic Veneer, and HPL.

Electrochemical Coating: This sub-type involves all surface treatment applied by using electrical charge. Because of these characteristics, these procedures are mostly used on metals.

Examples: Chromizing, Galvanizing, and Anodizing

Printing: This sub-type contains all techniques that apply specific figures to a surface.

Examples: Press, Print, Stamp, Offset, Laser-jet, and Laser-press

The type Orientation is introduced because the material and construction orientation can have

Uniaxial: This sub-type involves geometries of fibers that do not intersect when extended into infinity.

Biaxial: This sub-type involves geometries of fibers that intersect in a square corner.

Radial: This sub-type involves geometries of fibers that originate from a single point.

Multiaxial: This sub-type involves geometries of fibers that intersect in a distinctive pattern that is not biaxial or radial.

Amorphous: This sub-type involves geometries of fibers that intersect in a non-distinctive pattern.

The final type consists of Structural Systems as described in the same-titled book by Heino Engel. In the description of these systems, he focuses on visual explanation with regard to the design effects of the structures. In his work, he makes a distinction between form-active, surface-active, section-active, vector-active and hybrid systems. All systems are explored visually in different forms and application. This image oriented aspect of the work makes it very applicable to education in architecture, design and the arts (Engel, 2007).

From-Active Systems: This sub-type involves structures of flexible matter in which form and forces align (Engel, 2007).

Examples: Cable-, Tent-, Pneumatic-, and Arch structures.

Surface-Active Systems: This sub-type involves structures of rigid plates in which the redirection of forces is affected by surface resistance (Engel, 2007).

Examples: Flat-, Curved-, and Space trusses.

Section-Active Systems: This sub-type involves structures of solid linear elements in which the redirection of forces is effected by mobilization of sectional forces (Engel, 2007).

Examples: Beam-, Frame-, Grid-, and Slab structures.

Vector-Active Systems: This sub-type involves structures of bars in which the redirection of forces is effected by vector partition (Engel, 2007).

Examples: Plate-, Folded-, and Shell structures.

Height-Active Systems: This sub-type involves structures in which the redirection of forces necessitated by height extension.

Examples: Core- and Bridge high-rise.